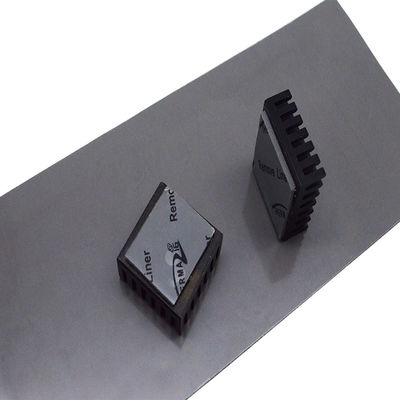

Produktspezifikation

Produkthöhe: 0,040 Zoll (1,0 mm) ~ 0,200 Zoll (5,00 mm)

Produktgrößen: 8" x 16" ((200mm x 400mm)

Für verschiedene Dicken können Sie uns kontaktieren.Weitere Informationen zu thermisch leitfähigen Materialien erhalten Sie bei uns.

Verpackungsdetails und Vorlaufzeit

Die Verpackung von Thermalpads

1.mit PET-Folien oder Schaumstoff zum Schutz

2. Verwenden Sie Papierkarte, um jede Schicht zu trennen.

3. Exportkarton innen und außen

4. die Anforderungen der Kunden erfüllen - individuell angepasst

Vorlaufzeit:Menge ((Stück):5000

Zeit (Tage): zu verhandeln.

Warum haben Sie uns gewählt?

1.Unsere Wertbotschaft lautet: "Machen Sie es beim ersten Mal richtig, vollständige Qualitätskontrolle".

2Unsere Kernkompetenzen sind thermisch leitfähige Schnittstellenmaterialien.

3.Produkte mit Wettbewerbsvorteil.

4Vertraulichkeitsvereinbarung Geschäftsgeheimnisvertrag.

5- Kostenloses Musterangebot.

6.Qualitätssicherungsvertrag.

Häufige Fragen:

F: Sind Sie Handelsgesellschaft oder Hersteller?

A: Wir sind Hersteller in China.

F: Welche Wärmeleitfähigkeit wird auf dem Datenblatt ermittelt?

A: Alle Daten in dem Blatt sind tatsächlich getestet. Zur Prüfung der Wärmeleitfähigkeit werden Hot Disk und ASTM D5470 verwendet.

F: Wie finde ich die richtige Wärmeleitfähigkeit für meine Anwendungen?

A: Es hängt von den Watt der Stromquelle, der Fähigkeit der Wärmeabgabe ab. Bitte teilen Sie uns Ihre detaillierten Anwendungen und die Leistung mit, damit wir die geeignetsten thermisch leitenden Materialien empfehlen können.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!